Direct-to-Film (DTF) Transfers have evolved from specialized printing to a booming trend in apparel, driven by technological advancements and the demand for custom t-shirts. Modern DTF printers offer exceptional precision, vibrant colors, and a smooth finish on diverse fabrics, enabling intricate designs. This versatility has opened new creative avenues for designers and businesses, who embrace DTF transfers for promotional merchandise and expressive fashion pieces. The technology's convenience, streamlining production processes and minimizing waste, makes it appealing to both artisans and large manufacturers. As consumer demand grows, DTF transfers are expected to maintain their popularity.

Direct-to-Film Transfers (DTFT) are revolutionizing the film industry, growing in popularity due to technological advancements that have democratized access to high-quality cinematic production. Once a privilege reserved for major studios, DTFT now empowers independent filmmakers and smaller productions to create visually stunning content with reduced post-production times and costs. This evolving trend is perfectly positioned to capitalize on the surge in global streaming services and on-demand content consumption.

- The Evolution of Direct-To-Film Transfers

- – Exploring the historical context and early beginnings of this process.

- – How technology advancements have made it more accessible and cost-effective.

The Evolution of Direct-To-Film Transfers

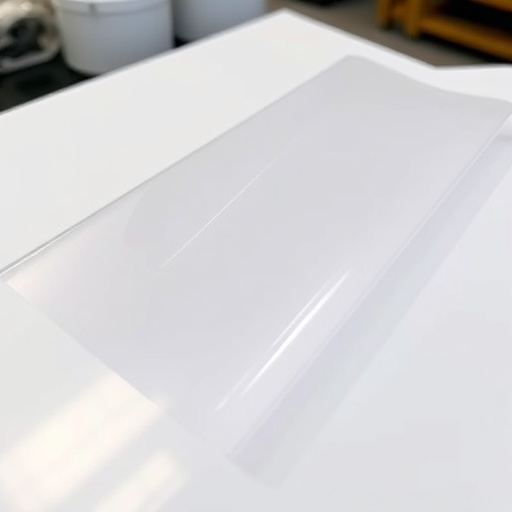

Direct-to-Film Transfers (DTF) have undergone a remarkable evolution, transforming from a niche printing method to a burgeoning trend in the apparel industry. This technology enables the application of intricate designs directly onto fabric using specialized equipment and inks, skipping the traditional screen printing process. The shift towards DTF transfers is driven by several factors, including advancements in technology, increased demand for custom t-shirts, and the desire for more efficient, cost-effective production methods.

Modern DTF printers offer unparalleled precision and detail, allowing for complex artwork, vibrant colors, and a smooth finish on various fabrics. This versatility has expanded the possibilities for designers and businesses, leading to a surge in custom dtf transfers for everything from promotional merchandise to expressive fashion statements. The convenience of direct-to-fabric printing has also caught the attention of many, as it streamlines production, reduces set-up times, and minimizes waste, making it an attractive option for both small-scale artisans and large-scale manufacturers.

– Exploring the historical context and early beginnings of this process.

The practice of Direct-to-Film Transfers (DTF) has evolved significantly over time, tracing its roots back to the early days of printing technology. Initially, this process was employed primarily for commercial printing on various materials, including textiles. With advancements in inkjet technology and digital printing, DTF found a new dimension, especially with the introduction of specialized heat transfer paper. This development opened doors for small businesses and entrepreneurs to leverage the technique for custom printing on demand, revolutionizing the t-shirt industry and other apparel sectors.

Over time, DTF printing has gained traction due to its versatility, cost-effectiveness, and ability to produce high-quality prints directly onto fabric. The use of dtf heat transfer paper allows for intricate designs and vibrant colors, making it a preferred method for creating custom garments, accessories, and promotional items. As the demand for unique, personalized products continues to grow, DTF transfers are expected to remain a popular choice among both consumers and businesses, further solidifying its place in the modern printing landscape.

– How technology advancements have made it more accessible and cost-effective.

The evolution of technology has significantly contributed to the rising popularity of Direct-To-Film (DTF) Transfers. Advancements in digital printing and imaging have made this process more accessible and cost-effective than ever before. Modern printers can now produce high-quality, vibrant DTF prints with remarkable speed and precision, eliminating the need for complex intermediate steps. This streamlines the production process, reducing costs for businesses, especially clothing brands looking to logos dft for clothing brands or custom designs onto garments.

Additionally, DTF transfers offer a wide range of benefits for various industries. For instance, in the apparel sector, dtf prints allow for on-demand production, enabling smaller batch sizes and minimizing waste. This flexibility is particularly appealing to businesses aiming to create unique, personalized products without incurring substantial setup costs. Moreover, DTF transfers can be applied to a diverse array of materials, expanding the possibilities for designers and manufacturers alike.

Direct-to-Film Transfers (DTFT) have evolved from a niche concept to a growing trend, driven by technological advancements that make it more accessible and cost-effective. As media consumption shifts towards digital platforms, DTFT offers a unique opportunity to preserve and share film content directly with audiences, circumventing traditional theatrical distribution channels. With its ability to provide high-quality experiences tailored for home viewing, DTFT is poised to revolutionize how we engage with cinema, giving rise to new possibilities for both filmmakers and viewers alike.