Direct-to-Film (DTF) Transfers revolutionize custom printing for dark fabrics, offering vibrant high-resolution prints with precise detail retention after washing. Popular among businesses due to efficiency and quality, DTF is ideal for creating durable apparel like hoodies. For packaging, choose compatible heat transfer paper, eco-friendly materials like PP bags or recycled kraft paper, and high-quality application tools like heat presses for a professional, captivating finish.

In today’s competitive market, efficient packaging is key to standing out. Direct-to-film transfers offer a revolutionary approach, allowing businesses to create unique and durable packaging solutions. This comprehensive guide explores the art of using Direct-to-Film Transfers for order packaging. From understanding the technology to selecting the right materials and equipment, we’ll walk you through each step. Learn how this innovative technique can enhance your brand visibility while ensuring product safety.

- Understanding Direct-to-Film Transfers: A Comprehensive Overview

- Choosing the Right Materials and Equipment for Efficient Packaging

- Step-by-Step Guide to Mastering Direct-to-Film Transfer Packaging Technique

Understanding Direct-to-Film Transfers: A Comprehensive Overview

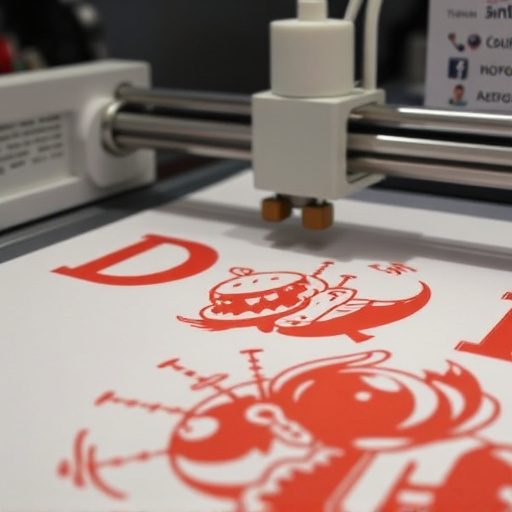

Direct-to-Film Transfers (DTF) is a cutting-edge technology revolutionizing the way we print custom designs onto various surfaces, particularly dark fabrics. Unlike traditional methods that rely on separate application steps for each color, DTF printing directly applies ink to the fabric through a specialized printer and heat press machine. This innovative process allows for vibrant, durable, and high-resolution prints, making it an ideal choice for creating custom apparel like hoodies and other textiles.

With DTF printing, businesses can effortlessly transition from designing to production in just a few steps. The technology offers unmatched precision, ensuring intricate details and fine lines are reproduced accurately on the final product. Moreover, DTF transfers are known for their longevity, resisting fading and cracking even after frequent washing, which is crucial for apparel items. This comprehensive overview highlights why custom DTF transfers are gaining popularity in the industry, providing a superior printing solution for businesses catering to diverse customer preferences.

Choosing the Right Materials and Equipment for Efficient Packaging

Selecting the appropriate materials and equipment is paramount when utilizing Direct-to-Film (DTF) transfers for packaging orders, especially for clothing brands looking to print logos on items like hoodies. The right choice can significantly streamline your packaging process, ensuring efficiency and maintaining high-quality standards. Opt for DTF heat transfer paper that’s compatible with your printer, offering vibrant colors and crisp details for visually appealing designs.

Consider durable and versatile packaging materials that cater to various product types. For instance, polypet (PP) bags or recycled kraft paper can be excellent choices, providing protection while aligning with eco-conscious consumer preferences. Additionally, invest in high-quality application tools like heat presses or iron-on transfers to achieve precise and even application of the DTF print onto garments, ensuring a professional finish that captivates customers.

Step-by-Step Guide to Mastering Direct-to-Film Transfer Packaging Technique

Direct-to-Film (DTF) Transfers have revolutionized packaging for clothing brands, offering a seamless way to apply intricate designs directly onto fabric. Mastering this technique ensures orders are packaged with precision and quality. Here’s a step-by-step guide:

1. Prepare Your Design: Start by creating or obtaining the design you want to transfer using graphic design software. Ensure it’s optimized for DTF printing, with appropriate resolution and color mode settings. For clothing brands, this could be logos, brand patterns, or creative illustrations.

2. Choose the Right Film: Select a DTF film suitable for your fabric type and desired finish. Different films offer variations in durability, glossiness, and adhesion. For logos dft for clothing, consider water-resistant films for outdoor wear or matte finishes for a subtle look on hoodies using dtf printing for hoodies.

3. Print and Apply: Using a specialized DTF printer, print your design directly onto the chosen film. Once dry, carefully peel the backing layer, leaving only the transfer film with the design intact. Align the film precisely with the fabric, ensuring no air bubbles are trapped. Press firmly to ensure adhesion.

Direct-to-Film transfers offer a cutting-edge packaging solution, allowing businesses to enhance their product presentation and protect items effectively. By understanding this technique and selecting the appropriate materials, you can streamline your order fulfillment process. The step-by-step guide provided offers a practical framework for implementing this method successfully. Embracing Direct-to-Film Transfers can indeed revolutionize your packaging strategy, ensuring efficient operations and satisfied customers.