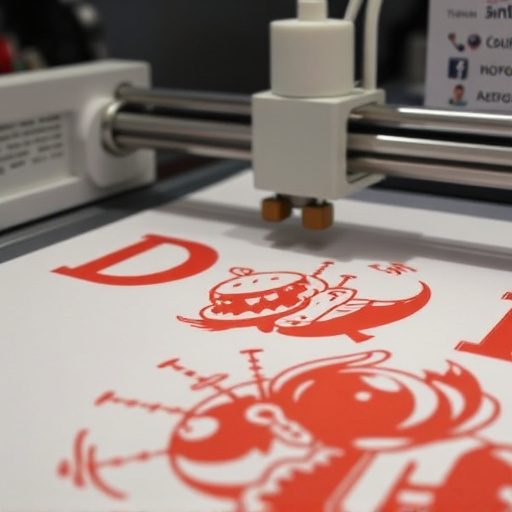

Direct-to-Film Transfers (DTF) is a cutting-edge printing technique for custom design creation, especially in apparel, eliminating the need for screens or plates. It offers fine details, vivid colors, and quick production, ideal for creating unique custom t shirts and promotional items. Choosing the right DTF transfer sheets with suitable coatings ensures superior adhesion and vibrant color reproduction. Mastering DTF requires careful consideration of printers, substrate preparation, alignment, and pressure application to create professional, long-lasting transfers for diverse projects.

“Unleash your creativity with Direct-to-Film (DTF) transfers—a game-changer for achieving vibrant, lasting results. This comprehensive guide equips you with the knowledge to become a pro at DTF applications. From grasping the fundamentals to selecting the perfect film and mastering technique, we’ll navigate you through every step. Discover how to transform your designs into indelible works of art on various surfaces, ensuring a professional finish that stands out. Let’s dive in and explore the world of DTF transfers!”

- Understanding Direct-To-Film Transfers: The Basics

- Choosing the Right Film and Coating for Optimal Results

- Mastering Application Techniques for Professional Finish

Understanding Direct-To-Film Transfers: The Basics

Direct-To-Film Transfers (DTF) is a cutting-edge printing technique revolutionizing the way businesses create custom designs for various products. This method involves transferring ink directly onto film or fabric using specialized equipment, offering unparalleled precision and vibrancy in prints. Unlike traditional printing methods that often require multiple steps and can be time-consuming, DTF streamlines the process, making it an attractive option for clothing brands looking to create unique custom t shirts and other promotional items with intricate logos dft for clothing brands.

By eliminating the need for screens or plates, DTF printing allows for complex designs with fine details and vivid colors. It’s particularly favored in the apparel industry for its ability to produce high-quality prints on various fabrics quickly and cost-effectively. Whether you’re a small business aiming to print a limited run of promotional merchandise or a large-scale manufacturer, understanding Direct-To-Film Transfers can empower you to make informed decisions about your printing needs and unlock creative possibilities with dtf prints.

Choosing the Right Film and Coating for Optimal Results

When it comes to Direct-to-Film (DTF) transfers, selecting the perfect film and coating is key to achieving exceptional results. The right film type should be chosen based on the application—whether for t-shirts, caps, or other products. High-quality dtf transfer sheets with a robust coating ensure optimal adhesion and vibrant color reproduction.

Consider factors like the material’s surface texture and porosity. For example, smooth fabric surfaces may require specific coatings to achieve clear, detailed prints, while rougher textures might benefit from different formulations. Using compatible film and coating combinations will guarantee that your DTF printing process yields professional-grade outcomes, enhancing the overall quality of your custom designs.

Mastering Application Techniques for Professional Finish

Mastering the art of applying Direct-to-Film (DTF) transfers is key to achieving a professional finish on various surfaces. The technique involves transferring designs from a film or digital source directly onto fabric, metal, wood, or other materials, and requires precision and practice. To start, choose the right DTF printer, ensuring it’s suitable for your intended applications and scale of production, whether for bulk DTF shirt production or creating custom logos for clothing brands.

Next, prepare your work surface and materials carefully. Clean the substrate to ensure optimal adhesion, and consider using release agents or backing papers as needed. Position the film precisely over the design area, aligning it meticulously to avoid bubbles or misalignments. Once in place, apply pressure evenly across the entire transfer to ensure a secure bond. With practice, you’ll develop a keen eye for detail, allowing you to produce vibrant, long-lasting DTF applications suitable for any project.

Direct-to-Film Transfers (DTFT) offer a professional finish for various projects, from signage to art pieces. By understanding the fundamentals, selecting the appropriate film and coating, and perfecting application techniques, you can achieve high-quality results. Mastering these steps ensures your DTFT projects stand out, delivering both aesthetic appeal and durability. Embrace these practices to elevate your work using this innovative technology.