Direct-to-Film (DTF) transfers revolutionize custom printing for t-shirts, bypassing traditional methods with direct application of designs to film using heat press machines after precise color calibration and preparation in graphic design software. Choosing a suitable heat press depends on production volume and design types, while successful application requires careful alignment, specific temperature and pressure settings, preheating, and cooling for accurate, long-lasting results.

Dive into the world of Direct-to-Film (DTF) transfers and unlock a versatile, efficient method for applying designs to various materials. This guide explores how to master the art using a heat press. From understanding DTF basics to selecting the perfect press, you’ll learn essential skills. We provide a step-by-step approach to ensure successful applications, allowing you to create stunning, long-lasting prints with ease.

- Understanding Direct-To-Film Transfers: Essential Basics

- Choosing the Right Heat Press for Your Needs

- Step-by-Step Guide: Applying Direct-To-Film Transfers Successfully

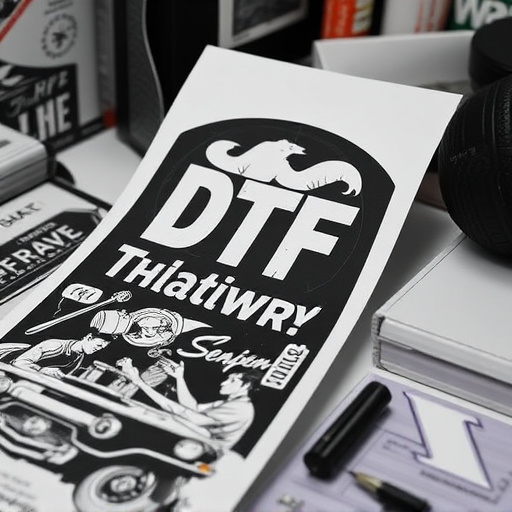

Understanding Direct-To-Film Transfers: Essential Basics

Direct-to-Film (DTF) transfers are a cutting-edge technique revolutionizing the custom printing industry. This method involves transferring designs directly onto film, eliminating the need for traditional ink and paper. It’s a game-changer for creating vibrant, durable prints on various materials, especially t-shirts. The process starts with high-quality graphic design software, where artists craft or upload their artwork, ensuring it meets specific requirements for dimensions and resolution.

Once designed, the image is prepared for printing by converting it into a format compatible with heat press machines. This involves a precise color calibration process to ensure accurate color reproduction. DTF for t-shirts offers an advantage over traditional methods as it allows for complex designs, vibrant colors, and smooth finishes, making it perfect for creating unique, personalized garments.

Choosing the Right Heat Press for Your Needs

When selecting a heat press for Direct-to-Film (DTF) transfers on garments, consider your production volume and the types of designs you’ll be applying. For small-scale or hobbyist use, a compact, manual press with variable temperature control might suffice, allowing you to experiment with various materials and achieve precise results. These presses are versatile and suitable for personalizing t-shirts, caps, and other textiles.

For higher-volume production or professional applications, an industrial heat press is the way to go. These machines offer larger plating areas, automated controls, and rapid heating capabilities. They’re built to handle thick materials and intricate designs seamlessly, making them ideal for dtf printing on a variety of garments, from custom sheets to full-scale clothing lines. Choose a model that aligns with your specific needs regarding size, heat settings, and pressure to ensure optimal performance and consistent quality in your DTF printing for t-shirts or other fabric items.

Step-by-Step Guide: Applying Direct-To-Film Transfers Successfully

Applying Direct-To-Film (DTF) Transfers successfully involves a meticulous process that ensures crisp, long-lasting designs on various materials. Start by preparing your work area with ample space and ensuring proper ventilation due to the heat involved. Next, select the appropriate DTF transfer film for your project, considering factors like material compatibility and desired design quality. Place the selected film face-down on a clean surface, aligning it carefully with the design you wish to transfer.

Using a heat press machine, set the temperature and pressure according to the manufacturer’s guidelines for the specific DTF transfer film. Preheat the press plate to the correct temperature before placing the material with the film face-up onto it. Once the press is ready, apply even pressure and maintain the recommended heat time for optimal results. After the cycle is complete, carefully remove the material from the press plate, allowing the transferred design to cool down before handling. This step-by-step approach ensures that your custom DTF transfers are applied accurately and securely, suitable for a range of applications including DTF for apparel.

Direct-to-Film Transfers (DTF) offer a versatile and efficient way to apply designs to various materials. By understanding the basics of DTF, selecting the appropriate heat press, and following a meticulous application process, you can achieve professional results at home or in a small business setting. This method revolutionizes the way we customize products, enabling us to create high-quality, indelible prints with ease.