Direct-to-Film (DTF) transfers revolutionize apparel printing with cutting-edge technology, enabling vibrant, detailed prints on dark fabrics in rapid time. This method uses a digital image transferred to film as a stencil, offering unparalleled versatility for custom designs while maintaining consistent quality. Ideal for small batches and single orders, DTF transforms the industry with its efficiency and innovation, requiring specialized films for optimal contrast and color accuracy based on fabric type. The process involves creating an optimized digital design, printing it onto transparent film, cutting and weeding unnecessary parts, then applying the film to substrates using heat and pressure.

Looking to elevate your packaging game with stunning designs? Discover the art of Direct-to-Film Transfers – a revolutionary method transforming the way brands package their orders. This comprehensive guide delves into the world of DTFT, offering insights on choosing the right materials for optimal results. Learn a step-by-step process from design to mastery, unlocking secrets to create packages that captivate and inspire.

- Understanding Direct-to-Film Transfers: A Comprehensive Guide

- Choosing the Right Materials for Optimal Results

- Step-by-Step Process: From Design to Packaging Mastery

Understanding Direct-to-Film Transfers: A Comprehensive Guide

Direct-to-Film Transfers (DTF) is a cutting-edge technology that enables the application of intricate designs directly onto various materials, particularly dark fabrics like hoodies and t-shirts. This method eliminates the need for traditional screen printing setups, streamlining the order packaging process significantly. With DTF printing, businesses can achieve vibrant, detailed prints in record time.

A direct to film printer facilitates this process by using a digital image that is transferred directly onto a film, which then acts as a stencil for the print. This versatile technique allows for custom designs and ensures consistent quality across orders. Moreover, it’s an efficient solution for small batch productions or even single-item custom orders, making it a game-changer in the apparel industry.

Choosing the Right Materials for Optimal Results

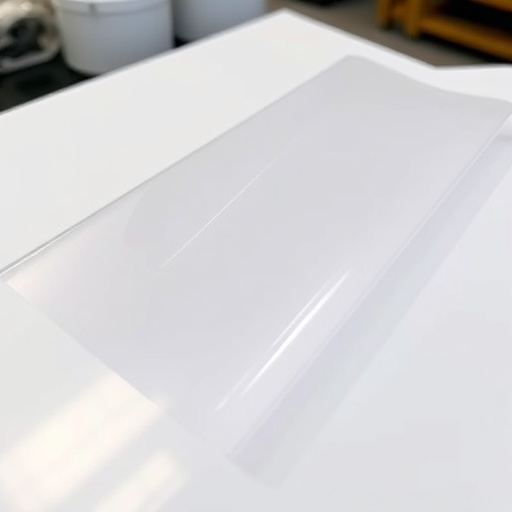

When packaging orders using Direct-to-Film (DTF) transfers, selecting the appropriate materials is key to achieving optimal results. The quality and type of film used directly impact the final print’s vibrancy, durability, and adhesion to various surfaces. For dtf printing on dark fabrics, choosing films designed for contrast and color accuracy is essential. These specialized films are formulated to bond tightly with fabric, ensuring graphics don’t crack or fade over time.

For Custom graphic tees, consider using DTF transfers that offer excellent opacity to prevent ink bleeding through from the substrate. Additionally, a smooth surface finish enhances the overall print quality, making images and text crisp and clear. Always refer to manufacturer guidelines for recommended film types based on your specific dtf printing needs and the type of fabric or material you’re working with.

Step-by-Step Process: From Design to Packaging Mastery

The process of packaging orders using Direct-to-Film (DTF) transfers is an art that involves a precise sequence of steps, from design to final application. It begins with creating a digital design, ensuring it’s optimized for DTF printing and ready for the specific substrate—be it a t-shirt, mug, or other merchandise. Once approved, the design is sent to a direct to film printer, which uses specialized equipment to precisely transfer the image onto a transparent film.

The printed film is then carefully cut and prepared for application. This involves weeding any unnecessary parts of the design while ensuring the remaining elements are intact. The weeded film is then ready to be applied to the substrate using heat and pressure. This step-by-step process, from initial design to final packaging, allows for precise, high-quality printing that offers vibrant colors and sharp details, making it ideal for dtf printing for t-shirts and other products.

Direct-to-Film Transfers offer a revolutionary approach to packaging, enabling businesses to create unique and visually appealing designs. By understanding the technology and selecting appropriate materials, you can master the art of packaging. The step-by-step process detailed in this article provides a comprehensive guide, from design conception to the final packaged product. Embracing Direct-to-Film Transfers allows for enhanced creativity, ensuring your products stand out on store shelves.