Direct-to-Film (DTF) Transfers are a cutting-edge printing technology that enables direct design transfer onto various surfaces, eliminating intermediate steps. This method offers enhanced durability and vibrant prints on materials like apparel, accessories, and promotional items. The process involves creating custom gang sheets with precise alignment for intricate designs, which are then pressed onto substrates using specialized ink and film. DTF is ideal for small batches, catering to the demand for personalized, unique products while providing efficient production, color accuracy, and customizable options through online platforms.

Direct-to-Film Transfers (DTF) are revolutionizing the custom printing industry, offering a streamlined process that eliminates the need for traditional platen-based methods. This innovative technology allows businesses to scale their operations efficiently while maintaining superior print quality. In this article, we’ll explore the intricacies of DTF, from understanding its fundamental process and benefits to uncovering strategies for successful scaling. We’ll also delve into the diverse market applications and significant growth potential of DTF in today’s competitive printing landscape.

- Understanding Direct-To-Film Transfers (DTF):

- – Definition and process overview

- – Benefits for custom printing businesses

Understanding Direct-To-Film Transfers (DTF):

Direct-to-Film Transfers (DTF) is a cutting-edge technology that has transformed the custom printing industry. Unlike traditional methods that rely on intermediate materials, DTF involves transferring designs directly onto various surfaces using specialized ink and film. This innovative approach offers several advantages, including superior durability and vibrant, long-lasting prints. With DTF, businesses can create high-quality, custom-designed products ranging from apparel to accessories and even promotional items.

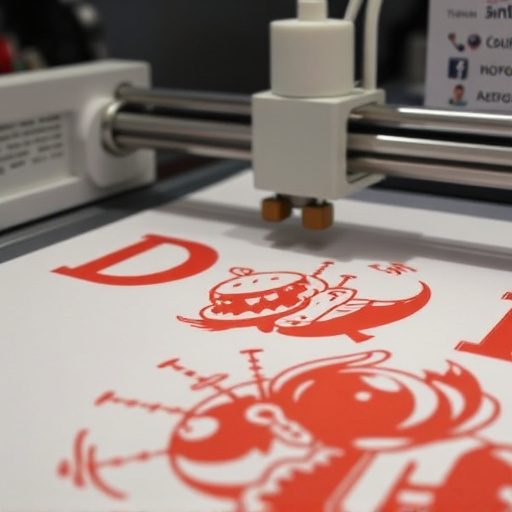

The process begins with creating custom gang sheets—sheets of film containing multiple design layers—which are then precisely aligned and pressed onto the desired substrate, such as textile or plastic. This method ensures consistency and accuracy in printing complex designs, making it ideal for small batches or one-off projects. Custom DTF transfers deliver exceptional results, enabling businesses to offer unique, personalized products that meet the evolving demands of modern consumers.

– Definition and process overview

Direct-to-Film (DTF) Transfers offer a cutting-edge solution for custom printing, revolutionizing the way businesses and artists approach product personalization. This innovative process involves transferring high-quality images directly onto various materials using specialized equipment and inks. In simple terms, it’s like painting on film, allowing for intricate designs and vibrant colors to be reproduced accurately.

The DTF transfer process begins with creating or obtaining a digital design that can be tailored to the client’s specifications. This design is then precisely aligned and printed onto a thin, flexible film using advanced printing technology. Once cured, this film is carefully transferred onto the desired substrate, such as fabric, metal, or wood, using heat and pressure. The result is a crisp, detailed print that retains the original artwork’s color accuracy and resolution, making it ideal for a range of applications from custom apparel to promotional items. Custom DTF transfers allow for unique, on-demand production, ensuring that each piece is tailored to individual preferences while maintaining consistent quality across orders.

– Benefits for custom printing businesses

Direct-to-Film (DTF) Transfers offer custom printing businesses a range of benefits that can significantly enhance their operations and product offerings. One of the key advantages is the ability to print directly onto various materials, from textiles to plastics and metals, without the need for intermediate surfaces. This streamlines production processes, reduces waste, and allows for faster turnaround times. DTF technology also provides exceptional color accuracy and detail, ensuring that every design is reproduced with precision.

Additionally, DTF heat press settings can be easily customized to suit different materials and design requirements, making it versatile for various printing projects. The convenience of online ordering further boosts customer satisfaction by enabling clients to place orders from the comfort of their homes, access a wide array of customization options, and track their products’ progress in real time. By adopting DTF Transfers, custom printing businesses can expand their capabilities, cater to diverse client needs, and stay competitive in today’s market.

Direct-to-Film Transfers (DTF) offer a revolutionary approach to custom printing, enabling businesses to scale their operations efficiently. By eliminating the need for traditional ink and media, DTF allows for faster production times, cost savings, and superior print quality. This technology is particularly beneficial for businesses looking to cater to diverse customer demands, ensuring consistent and high-impact results. Embracing DTF can be a game-changer, streamlining workflows and opening doors to new creative possibilities in the world of custom printing.